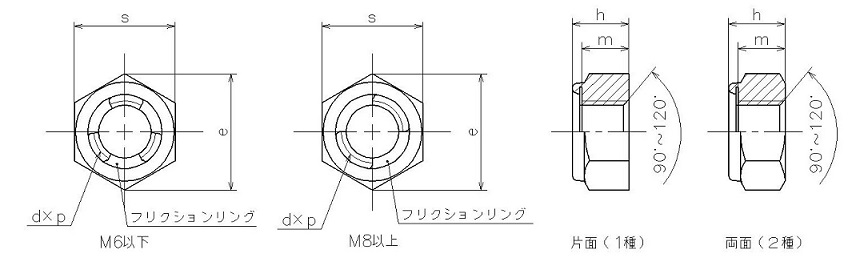

U-NUT片面(1種) 両面(2種)

ゆるみ止めナットの標準品

寸法表

寸法表 U-NUT 片面(1種) 両面(2種)

●生産品

ねじ精度:JIS6H(2級) 単位:mm

| ナット本体材質 | SS400 | S45C(調質) | SUS304 | 単重 (g) 約 |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| フリクションリング材質 | SUS301 | |||||||||||

| 呼び径 (d) |

ピッチ (p) |

二面幅(s) | 全高(h) | ねじ高さ (m) 約 |

対角 (e) 約 |

片面 (1種) |

両面 (2種) |

両面 (2種) |

片面 (1種) |

|||

| 基準 寸法 |

許容差 | 基準 寸法 |

許容差 | |||||||||

| M3 | 0.5 | 5.5 |

0

-0.2 |

3.2 | ±0.3 | 2.7 | 6.4 | ● | ● | 0.4 | ||

| M4 | 0.7 | 7.0 | 3.8 | 3.0 | 8.1 | ● | ● | 0.8 | ||||

| M5 | 0.8 | 8.0 | 4.6 | 3.9 | 9.2 | ● | ● | ● | 1.2 | |||

| M6 | 1 | 10.0 | 5.1 | 4.2 | 11.5 | ● | ● | ● | 2.1 | |||

| M8 | 1.25 | 13.0 |

0

-0.25 |

7.3 | ±0.4 | 6.1 | 15.0 | ● | ● | ● | 5.1 | |

| 1 | ● | ● | ● | |||||||||

| M10 | 1.5 | 17.0 | 8.3 | 7.1 | 19.6 | ● | ● | ● | 10.0 | |||

| 1.25 | ● | ● | ● | |||||||||

| M12 | 1.75 | 19.0 |

0

-0.35 |

10.5 | 9.0 | 21.9 | ● | ● | ● | 15.2 | ||

| 1.5 | ● | ● | ● | |||||||||

| 1.25 | ● | ● | ● | |||||||||

| M14 | 2 | 22.0 | 12.5 | ±0.5 | 11.0 | 25.4 | ● | ● | ● | 24.0 | ||

| 1.5 | ● | ● | ● | |||||||||

| M16 | 2 | 24.0 | 14.5 | 13.0 | 27.7 | ● | ● | ● | 31.5 | |||

| 1.5 | ● | ● | ● | |||||||||

| M18 | 2.5 | 27.0 | 16.0 | 14.0 | 31.2 | ● | ● | ● | 45.2 | |||

| 1.5 | ● | ● | ● | |||||||||

| M20 | 2.5 | 30.0 | 17.5 | 15.4 | 34.6 | ● | ● | ● | 61.4 | |||

| 1.5 | ● | ● | ● | |||||||||

| M22 | 2.5 | 32.0 |

0

-0.4 |

19.5 | ±0.6 | 17.2 | 37.0 | ● | ● | ● | 74.3 | |

| 1.5 | ● | ● | ● | |||||||||

| M24 | 3 | 36.0 | 21.5 | 18.8 | 41.6 | ● | ● | ● | 108.0 | |||

| 2 | ● | ● | ● | |||||||||

| M27 | 3 | 41.0 | 24.0 | 21.2 | 47.3 | ● | ● | ● | 159.0 | |||

| M30 | 3.5 | 46.0 | 27.0 | ±0.8 | 24.0 | 53.1 | ● | ● | ● | 226.0 | ||

| 3 | ● | ● | ● | |||||||||

| M33 | 3.5 | 50.0 | 29.5 | 26.5 | 57.7 | ● | ● | ● | 287.0 | |||

| 3 | ● | ● | ||||||||||

| M36 | 4 | 55.0 |

0

-0.45 |

32.5 | ±1 | 29.5 | 63.5 | ● | ● | ● | 393.0 | |

| 3 | ● | ● | ● | |||||||||

| M39 | 4 | 60.0 | 35.0 | 31.8 | 69.3 | ● | ● | ● | 509.0 | |||

| 3 | ● | ● | ||||||||||

| M42 | 4.5 | 65.0 | 38.0 | ±1.5 | 34.5 | 75.0 | ● | ● | ● | 651.0 | ||

| 3 | ● | ● | ||||||||||

| M45 | 4.5 | 70.0 | 40.0 | 36.0 | 80.8 | ● | ● | ● | 794.0 | |||

| 3 | 36.5 | ● | ● | |||||||||

| M48 | 5 | 75.0 | 42.0 | 38.0 | 86.5 | ● | ● | ● | 972.0 | |||

| 3 | ● | ● | ||||||||||

| M52 | 5 | 80.0 | 46.0 | ±2 | 42.0 | 92.4 | ● | ● | 1,190.0 | |||

| 3 | ● | ● | ||||||||||

| M55 | 3 | 85.0 |

0

-0.55 |

49.0 | 44.5 | 98.1 | ● | ● | 1,360.0 | |||

| M56 | 5.5 | ● | ● | 1,410.0 | ||||||||

| 4 | 45.0 | ● | ● | |||||||||

| M60 | 5.5 | 90.0 | 52.0 | 47.5 | 104.0 | ● | ● | 1,660.0 | ||||

| 4 | 48.0 | ● | ● | |||||||||

| M64 | 6 | 95.0 | 54.0 | 50.0 | 110.0 | ● | ● | 1,910.0 | ||||

| 4 | ● | ● | ||||||||||

参考締付けトルク表

参考締付けトルク表 U-NUT 片面(1種)両面(2種) ナット材質 SS400

下表の参考締付けトルクは、ボルトの表面処理及び強度区分を基準にした場合の参考値です。単位:N・m

| 表面処理 | 生地 | 電気亜鉛めっき | 溶融亜鉛めっき | |

|---|---|---|---|---|

| 呼び径 | ピッチ(mm) | ボルト強度区分:4.8 | ボルト強度区分:4.8 | ボルト強度区分:4.8 |

| M3 | 0.5 | 0.8 | 0.9 | ー |

| M4 | 0.7 | 1.8 | 2.2 | ー |

| M5 | 0.8 | 3.7 | 4.4 | ー |

| M6 | 1 | 6.3 | 7.4 | ー |

| M8 | 1.25 | 15.0 | 18.0 | 23.0 |

| 1 | 16.0 | 19.0 | ー | |

| M10 | 1.5 | 30.0 | 36.0 | 45.0 |

| 1.25 | 32.0 | 38.0 | ー | |

| M12 | 1.75 | 53.0 | 62.0 | 79.0 |

| 1.5 | 55.0 | 65.0 | ー | |

| 1.25 | 57.0 | 68.0 | ー | |

| M14 | 2 | 84.0 | 99.0 | 125.0 |

| 1.5 | 91.0 | 105.0 | ー | |

| M16 | 2 | 130.0 | 155.0 | 195.0 |

| 1.5 | 140.0 | 165.0 | ー | |

| M18 | 2.5 | 180.0 | 210.0 | 270.0 |

| 1.5 | 200.0 | 240.0 | ー | |

| M20 | 2.5 | 255.0 | 300.0 | 385.0 |

| 1.5 | 280.0 | 335.0 | ー | |

| M22 | 2.5 | 345.0 | 410.0 | 520.0 |

| 1.5 | 380.0 | 450.0 | ー | |

| M24 | 3 | 440.0 | 520.0 | 660.0 |

| 2 | 480.0 | 565.0 | ー | |

| M27 | 3 | 640.0 | 760.0 | 970.0 |

| M30 | 3.5 | 880.0 | 1,040.0 | 1,320.0 |

| 3 | 905.0 | 1,070.0 | ー | |

| M33 | 3.5 | 1,190.0 | 1,410.0 | 1,800.0 |

| 3 | 1,230.0 | 1,450.0 | ー | |

| M36 | 4 | 1,530.0 | 1,810.0 | 2,310.0 |

| 3 | 1,620.0 | 1,920.0 | ー | |

| M39 | 4 | 1,980.0 | 2,340.0 | 2,980.0 |

| 3 | 2,090.0 | 2,470.0 | ー | |

| M42 | 4.5 | 2,450.0 | 2,900.0 | 3,690.0 |

| 3 | 2,640.0 | 3,130.0 | ー | |

| M45 | 4.5 | 3,070.0 | 3,630.0 | 4,620.0 |

| 3 | 3,280.0 | 3,880.0 | ー | |

| M48 | 5 | 3,670.0 | 4,350.0 | 5,530.0 |

| 3 | 3,990.0 | 4,730.0 | ー | |

| M52 | 5 | 4,760.0 | 5,640.0 | 7,180.0 |

| 3 | 5,140.0 | 6,090.0 | ー | |

| M55 | 3 | 6,120.0 | 7,250.0 | ー |

| M56 | 5.5 | 5,910.0 | 7,000.0 | 8,910.0 |

| 4 | 6,230.0 | 7,380.0 | ー | |

| M60 | 5.5 | 7,360.0 | 8,720.0 | 11,100.0 |

| 4 | 7,740.0 | 9,170.0 | ー | |

| M64 | 6 | 8,920.0 | 10,550.0 | 13,450.0 |

| 4 | 9,480.0 | 11,240.0 | ー | |

参考締付けトルク表 U-NUT 片面(1種)両面(2種) ナット材質 S45C

下表の参考締付けトルクは、ボルトの表面処理及び強度区分を基準にした場合の参考値です。溶融亜鉛めっきにつきましてはナットの表面処理及び強度区分を基準にした場合の参考値です。

単位:N・m

| 表面処理 | 生地 | 電気亜鉛めっき | 溶融亜鉛めっき | |

|---|---|---|---|---|

| 呼び径 | ピッチ(mm) | ボルト強度区分:8.8 | ボルト強度区分:8.8 | ボルト強度区分:8.8 |

| M5 | 0.8 | 7.4 | 8.7 | ー |

| M6 | 1 | 13.0 | 15.0 | ー |

| M8 | 1.25 | 30.0 | 36.0 | 35.0 |

| 1 | 33.0 | 39.0 | ー | |

| M10 | 1.5 | 60.0 | 71.0 | 70.0 |

| 1.25 | 64.0 | 75.0 | ー | |

| M12 | 1.75 | 105.0 | 125.0 | 120.0 |

| 1.5 | 110.0 | 130.0 | ー | |

| 1.25 | 115.0 | 135.0 | ー | |

| M14 | 2 | 165.0 | 200.0 | 195.0 |

| 1.5 | 180.0 | 215.0 | ー | |

| M16 | 2 | 260.0 | 310.0 | 300.0 |

| 1.5 | 280.0 | 330.0 | ー | |

| M18 | 2.5 | 360.0 | 425.0 | 410.0 |

| 1.5 | 405.0 | 480.0 | ー | |

| M20 | 2.5 | 510.0 | 600.0 | 580.0 |

| 1.5 | 565.0 | 670.0 | ー | |

| M22 | 2.5 | 690.0 | 820.0 | 800.0 |

| 1.5 | 760.0 | 900.0 | ー | |

| M24 | 3 | 880.0 | 1,040.0 | 1,010.0 |

| 2 | 960.0 | 1,140.0 | ー | |

| M27 | 3 | 1,290.0 | 1,530.0 | 1,480.0 |

| M30 | 3.5 | 1,750.0 | 2,070.0 | 2,020.0 |

| 3 | 1,810.0 | 2,150.0 | ー | |

| M33 | 3.5 | 2,380.0 | 2,820.0 | 2,750.0 |

| 3 | 2,460.0 | 2,910.0 | ー | |

| M36 | 4 | 3,060.0 | 3,620.0 | 3,530.0 |

| 3 | 3,240.0 | 3,840.0 | ー | |

| M39 | 4 | 3,960.0 | 4,690.0 | 4,570.0 |

| 3 | 4,180.0 | 4,950.0 | ー | |

| M42 | 4.5 | 4,890.0 | 5,800.0 | 5,650.0 |

| 3 | 5,290.0 | 6,260.0 | ー | |

| M45 | 4.5 | 6,130.0 | 7,260.0 | 7,080.0 |

| 3 | 6,550.0 | 7,760.0 | ー | |

| M48 | 5 | 7,340.0 | 8,690.0 | 8,470.0 |

| 3 | 7,990.0 | 9,460.0 | ー | |

| M52 | 5 | 9,520.0 | 11,300.0 | ー |

| 3 | 10,300.0 | 12,150.0 | ー | |

| M55 | 3 | 12,250.0 | 14,500.0 | ー |

| M56 | 5.5 | 11,800.0 | 14,000.0 | 13,650.0 |

| 4 | 12,450.0 | 14,750.0 | ー | |

| M60 | 5.5 | 14,750.0 | 17,450.0 | 17,000.0 |

| 4 | 15,500.0 | 18,350.0 | ー | |

| M64 | 6 | 17,850.0 | 21,150.0 | 20,600.0 |

| 4 | 18,950.0 | 22,450.0 | ー | |

参考締付けトルク表 U-NUT 片面(1種)両面(2種) ナット材質 SUS304

単位:N・m

| 表面処理 | 生地 | |||

|---|---|---|---|---|

| ボルト | ||||

| 呼び径 | ピッチ(mm) | ステンレス 耐力300N/㎟ |

強度区分50 210N/㎟ |

強度区分70 450N/㎟ |

| M3 | 0.5 | 0.8 | 0.6 | 1.2 |

| M4 | 0.7 | 1.9 | 1.3 | 2.8 |

| M5 | 0.8 | 3.8 | 2.7 | 5.8 |

| M6 | 1 | 6.5 | 4.6 | 9.8 |

| M8 | 1.25 | 16.0 | 11.0 | 24.0 |

| 1 | 17.0 | 12.0 | 25.0 | |

| M10 | 1.5 | 31.0 | 22.0 | 47.0 |

| 1.25 | 33.0 | 23.0 | 50.0 | |

| M12 | 1.75 | 55.0 | 38.0 | 82.0 |

| 1.5 | 57.0 | 40.0 | 86.0 | |

| 1.25 | 60.0 | 42.0 | 90.0 | |

| M14 | 2 | 87.0 | 61.0 | 130.0 |

| 1.5 | 95.0 | 66.0 | 140.0 | |

| M16 | 2 | 135.0 | 95.0 | 205.0 |

| 1.5 | 145.0 | 100.0 | 215.0 | |

| M18 | 2.5 | 185.0 | 130.0 | ー |

| 1.5 | 210.0 | 145.0 | ー | |

| M20 | 2.5 | 265.0 | 185.0 | ー |

| 1.5 | 295.0 | 205.0 | ー | |

| M22 | 2.5 | 360.0 | 250.0 | ー |

| 1.5 | 395.0 | 275.0 | ー | |

| M24 | 3 | 455.0 | 320.0 | ー |

| 2 | 495.0 | 350.0 | ー | |

| M27 | 3 | 670.0 | 470.0 | ー |

| M30 | 3.5 | 910.0 | 635.0 | ー |

| 3 | 940.0 | 660.0 | ー | |

| M33 | 3.5 | 1240.0 | 865.0 | ー |

| M36 | 4 | 1590.0 | 1,110.0 | ー |

| 3 | 1680.0 | 1,180.0 | ー | |

| M39 | 4 | 2060.0 | 1,440.0 | ー |

| M42 | 4.5 | 2540.0 | 1,780.0 | ー |

| M45 | 4.5 | 3180.0 | 2,230.0 | ー |

| M48 | 5 | 3810.0 | 2,670.0 | ー |