Manufactured with Fuji Seimitsu’s latest equipment and cutting-edge technology, the FUJILOK U-NUT stably exhibits a high locking effect. Fuji Seimitsu possesses a variety of testing and measurement equipment and performs various tests and inspections to ensure the high performance and stable quality of our products. U-NUTs conform to various safety standards and have the highest level of quality control, allowing them to be used with peace of mind.

In this article, we will introduce Fuji Seimitsu's test and measurement equipment along with the types of tests we conduct.

Tests and inspection methods related to nuts

There are various tests and inspections related to nuts. For example, under Japanese standards, there are tests such as the guaranteed load test specified by JIS (JIS B 1052: Carbon Steel and Alloy Steel Fasteners—Mechanical Properties), the prevailing torque test (JIS B 1056: Prevailing Torque Steel NutsーMechanical Properties and Performance), and the screw fastening characteristic test (JIS B 1084: Fasteners—Torque/Clamp Force Testing). The NAS Confirming High-Speed Thread Losseness Test(NAS3350 National Aerospace Specification for impact type vibration test at right angle to shaft) and the Junker Type Thread Loosening Test(DIN 65151 German industrial standard for vibration test at right angle to shaft) are examples of screw loosening tests.

Projectors, microscopes, surface roughness meters, and other devices can be used to measure surface scratches and strains as well as the dimensional accuracy of nuts. We also use equipment such as a fluorescent X-ray coating thickness gauge for measuring the thickness of plating on surface-treated nuts and torque wrenches for measuring actual fastening torque.

Microscope inspection

Without inspection or measuring devices, these tests and inspections would have to be done at an industrial testing center. Because of the time and expense involved, it’s not easy to continue and do these tests in detail. Fuji Seimitsu possesses these inspection and measurement equipment and is equipped to conduct tests and inspections in-house. We also regularly update our equipment to achieve more advanced and extensive testing and inspection.

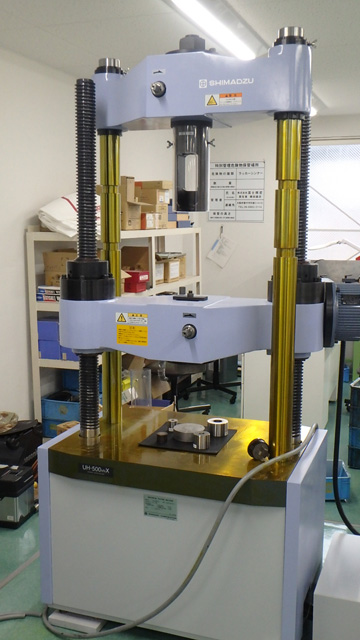

Guaranteed load testing with a universal testing machine

Fuji Seimitsu adopted new testing equipment in 2021. One of these is the digital Amsler universal tensile testing machine (UH-500kNX manufactured by Shimadzu Corporation), which can handle loads of up to 50 tons. This equipment is used for the guaranteed load test specified by JIS.

A digital Amsler universal tensile testing machine

Guaranteed load is the load that can be withstood without causing permanent elongation or distortion of the nut threads. The guaranteed load test uses a jig to apply the guaranteed load force to the nut axially and hold it with that force for 15 seconds to ensure that the nut threads can withstand that force without shear failure or fracture. After stopping the load of the guaranteed load test force, it must be possible to then remove the nut in the same manner as before the force was applied. Doing so shows that the nut threads won’t fail, and the nut can be tightened as well as removed without issue as long as the stress on the nut is within the guaranteed load.

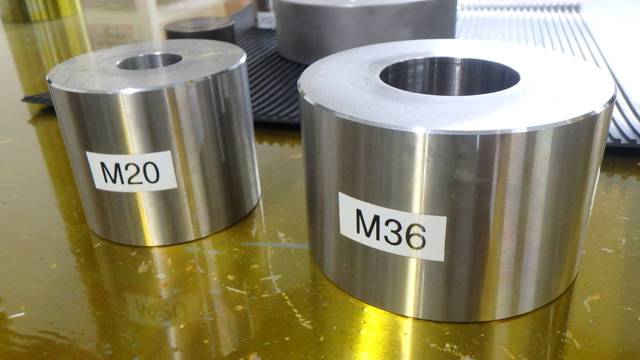

A variety of jigs are available

We have had similar equipment for a long time, but the maximum load was 30 tons and the size of the nuts that could be measured was limited. Having equipment that reaches 50 tons of load greatly expands the targets we can measure. In the past, we used analog testing equipment, which made it difficult to digitally process data and automatically perform setting operations. With our new testing equipment, it is possible to edit test results as digital data and then pass that data over to our customers.

Threaded Fastener Tightening Characteristics Testing Machine

Another new testing device that we adopted in 2021 is the threaded fastener tightening characteristics testing machine. A Threaded Fastener Tightening Characteristics Testing Machine can test characteristics based on JIS standards. This includes the bearable force as well as other forces and coefficients that are generated when fastening nuts, such as tightening torque, axial force, yield tightening torque, the total friction coefficient, the thread surface friction coefficient, and the seat surface friction coefficient.

Threaded Fastener Tightening Characteristics Testing Machine

In the past, we had a Threaded Fastener Tightening Characteristics Testing Machine that supported thread diameters from 8 mm to 24 mm. We have since adopted two new models, one that supports small diameters from 3 mm to 6 mm (the NST-100NM made by Japan Instrumentation System) and another that supports large diameters from 50 mm to 75 mm (the NST-3000NM made by Japan Instrumentation System).

Conventionally, there has been a demand for testing nuts with smaller and larger diameters, but with our newly adopted Threaded Fastener Tightening Characteristics Testing Machine, it is now possible to handle nuts with a wide range of diameters.

Prevailing Torque Testing Machine

There is one more piece of testing equipment that we have newly adopted. It’s a prevailing torque testing machine (the NST-20NM made by Japan Instrumentation System). the FUJILOK U-NUT features a friction ring that has been secured to and integrated with the top face of the nut body. the FUJILOK U-NUT’s friction ring generates prevailing torque, which then produces a locking effect. With our newly adopted testing machine, it is possible to test the value of the prevailing torque that is generated when tightening the nut according to JIS standards. It is also possible to test reductions in prevailing torque that occur through repeated tightening. These tests determine the amount of locking effect the FUJILOK U-NUT has.

Prevailing Torque Testing Machine

We support various tests and inspections.

Inspection results

At Fuji Seimitsu, the results of tests and inspections conducted using our own test and measurement equipment can be submitted to our customers. If we receive a request for the results of tests and inspections of our products, we will respond immediately. Also, for customers who are considering using the FUJILOK U-NUT, we offer support by utilizing our equipment as requested to test, check, and provide data to determine if the FUJILOK U-NUT will satisfy their performance needs. Fuji Seimitsu can also provide support to customers who have problems with the nuts or bolts they are using. Using various types of equipment, we conduct a variety of tests to resolve challenges.