Fuji Seimitsu's strength lies not only in our track record and the quality that we have come to achieve but also in our quality control system, robust after-sales support, and maintenance support, which support our track record and quality. Fuji Seimitsu resolves the challenges that our customers experience with nuts and bolts.

The secret of the FUJILOK U-NUT’s locking effect

the FUJILOK U-NUT can demonstrate a locking effect on its own without the use of methods involving thread-locking fluid or double nuts. As a result, it can be used in places where thread-locking fluid can’t be used, such as inside food processing machines, and you can prevent a nut from dropping out with a single, standard-sized nut.

The secret to why the FUJILOK U-NUT doesn’t loosen is the friction ring (specialized spring), which is secured to and integrated with the top face of the nut body by crimping. When the FUJILOK U-NUT is tightened onto the bolt, the friction ring comes into contact with the thread portion of the bolt. Further tightening the nut causes the friction ring to begin to bend along with the screw thread and presses against the bolt screw threads. When this happens, the force of the spring attempting to return to its original state (stress) and the force of the bolt and nut screw pulling each other (reaction force) generate prevailing torque (friction torque). the FUJILOK U-NUT does not loosen due to the effect of prevailing torque. By turning it with a tool, it can be installed in the same way as a general nut, and it prevents early dropout caused by a decrease in axial force. In addition, as long as the friction ring is tightened at the position where it is firmly pressed against the screw threads, it is possible to demonstrate a locking effect, even if the nut is screwed to the middle of the bolt.

How the FUJILOK U-NUT works

the FUJILOK U-NUT is already used in more than 20 products genres, including motorcycles, automobiles, special-equipped vehicles, transportation equipment, railways, shipbuilding, construction equipment, farm equipment, electronics, plants, processing equipment, machinery, civil engineering, construction, materials, playground equipment, industrial robots, machine tools, and conveyors. the FUJILOK U-NUT is a locknut that does not loosen even in harsh operating environments and provides high levels of safety and security with high quality and reliability.

The FUJILOK U-NUT strengths: A manufacturing and quality control system that maintains high quality

One of the strengths of the FUJILOK U-NUT is the stability of its quality. the FUJILOK U-NUT is used in many critical safety components due to its high locking effect and ease of handling. In the case of parts that affect human lives, nuts cannot be allowed to loosen and drop out during use. Moreover, nuts should not become loose and drop out due to product defects.

the FUJILOK U-NUT is manufactured using Fuji Seimitsu's latest equipment and cutting-edge technology. There is no variation in quality, and it continues to stably exhibit a high locking effect. In addition, each and every one of our employees is committed to quality control with a high level of awareness for handling products related to safety and security. Only products that meet various safety standards and the highest level of quality control are shipped. This allows our customers to use the FUJILOK U-NUT with peace of mind.

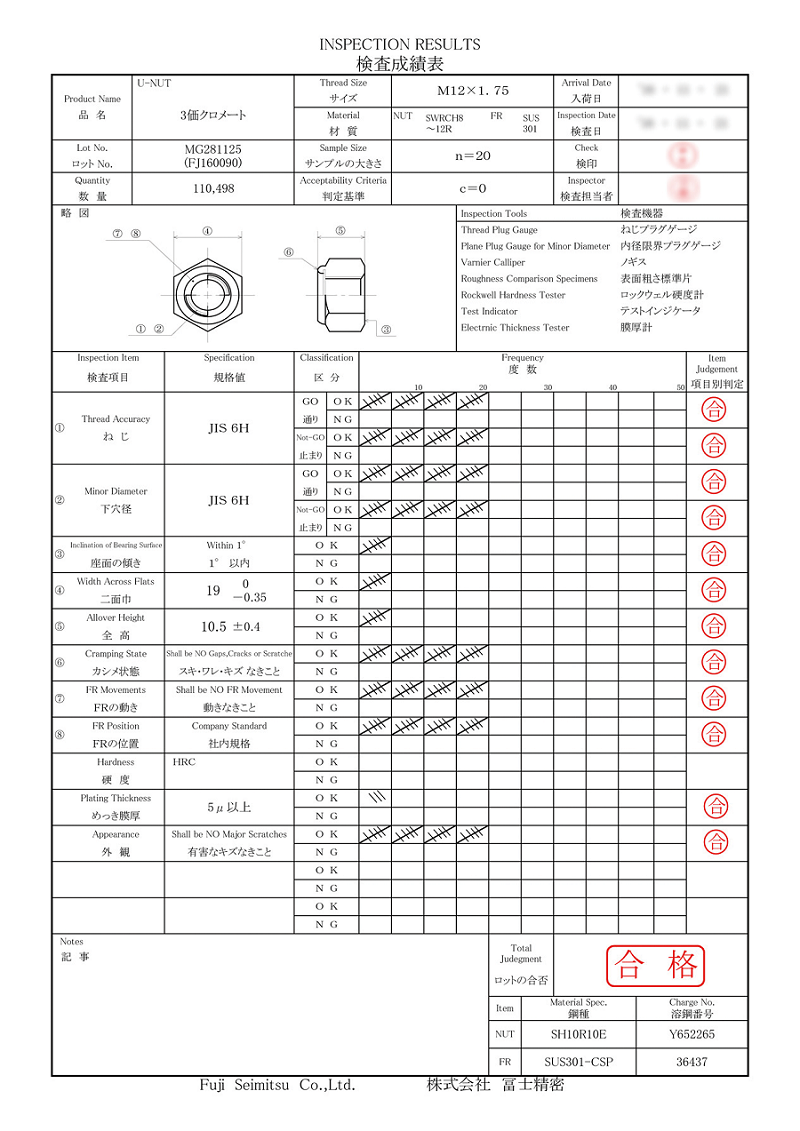

Quality inspection

To ensure the stability of the performance and quality of the FUJILOK U-NUT, Fuji Seimitsu has a variety of test equipment in-house. We have a digital Amsler universal tensile testing machine that supports loads of up to 50 tons; threaded fastener tightening characteristics testing machines that support large and small diameters; a NAS Confirming High-Speed Thread Looseness Testing Machine manufactured in accordance with NAS3350 (National Aerospace standard) tester specifications; and a Junker Testing Machine for Thread Loosning that verifies fastening force and vibration resistance. In addition, we have a variety of measuring devices for measuring scratches and surface conditions. The measured data can also be submitted to customers as a report. This allows our customers to also confirm the high performance and stability of the FUJILOK U-NUT’s quality with figures.

Digital universal tensile testing machine

The FUJILOK U-NUT Strengths: The responsiveness of our after-sales service

Another strength of the FUJILOK U-NUT is Fuji Seimitsu's high responsiveness and extensive after-sales service. In the unlikely event that a defect occurs in a product being used by a customer or if there is a problem that is difficult to solve, Fuji Seimitsu will respond to all problems until the very end. We handle issues not only with our own products but even with nuts manufactured by other companies. We investigate the causes of problems associated with nuts by verifying them using various test equipment and by conducting interviews to reproduce usage conditions. We then prepare a report based on the test data and suggest countermeasures as well as improvements. After the proposal has been made, we will check with the customer again at a later time, and we will not stop checking in until we hear from the customer that there is no problem. This allows customers to use nuts with performance and safety that meets their satisfaction.

Inspection results

In addition, when using the FUJILOK U-NUT for prototype or research-stage equipment, we are able to conduct tests in advance to see if the FUJILOK U-NUT can demonstrate sufficient performance. It is possible to provide data to customers by conducting tests using the various measuring equipment we have. In addition, we can create special custom-made shapes. We carry many shapes, such as the Cap Type U-NUT and the Weld Type U-NUT, as well as a wide range of sizes from M3 to M115, but we can also design and manufacture products to meet customer requirements. Fuji Seimitsu has a wide network across Japan and overseas, and we are fully equipped not only for manufacturing and installation, but also for after-sales service following delivery.

Feel free to contact us for custom-made products as well

the FUJILOK U-NUT supports a safe and secure society

From its inception to today, the FUJILOK U-NUT has been trusted by many customers for its high performance as well as its stable quality, and it has been used in great numbers. More than 200 million U-NUTs are still shipped annually. If you look around, there’s probably something near you using U-NUTs. For example, the FUJILOK U-NUT is used in famous architectural structures such as the Honshu-Shikoku Bridge Project, Rainbow Bridge, the Tokyo Skytree, and Abeno Harukas. the FUJILOK U-NUT proudly accounts for approximately 80% of the locknuts used in Japanese motorcycles. They’re also used to secure noise barrier walls on highways and the Shinkansen. They may also be used in the cars running in front of you, construction equipment on construction sites, or manufacturing equipment running in a nearby factory. You won’t only find the FUJILOK U-NUT in Japan, it’s are also used in Europe, the United States, Asia, Oceania, and other countries around the world.

The FUJILOK U-NUTs are used in all kinds of places.

Fuji Seimitsu has refined its technology, established a robust inspection system, and has come to accumulate achievements and continually build upon the quality of our products. In addition, we believe that we have gained the trust of our customers by providing sufficient after-sales service. Fuji Seimitsu will continue to respond flexibly and from a variety of angles to the challenges that our customers experience with nuts and bolts.