SU-NUT

FUJILOK U-NUT + theft/tamper prevention

Features

- Prevents theft and tampering simply by replacing the nut

- Has the same functions and quality as the FUJILOK U-NUT

- Requires a dedicated socket for tightening

General names

Anti-theft nut, Tamper-proof nut

Video of features

Applicable markets

- Two-wheeled vehicles

- Four-wheeled vehicles

- Special-equipped vehicles

- Farm equipment

- Conveyers

- Railways

- Marine vessels

- Plants

- Machine tools

- Industrial equipment

- Electronics

- Medical care and welfare

- Infrastructure

- Civil engineering

- Architecture

- Playground equipment

Basic Information

Specs

| Applications | Solar panels, towers, signs, guardrails, marine equipment, outdoor signage, vending machines, surveillance cameras, nameplates, game equipment, public facilities (toilets), hotel equipment (lighting equipment), etc. |

|---|---|

| Thread accuracy | JIS6H (JIS Class 2) |

| Sizes | M6 *Pitch: Coarse thread |

| Materials | SUS304 or equivalent |

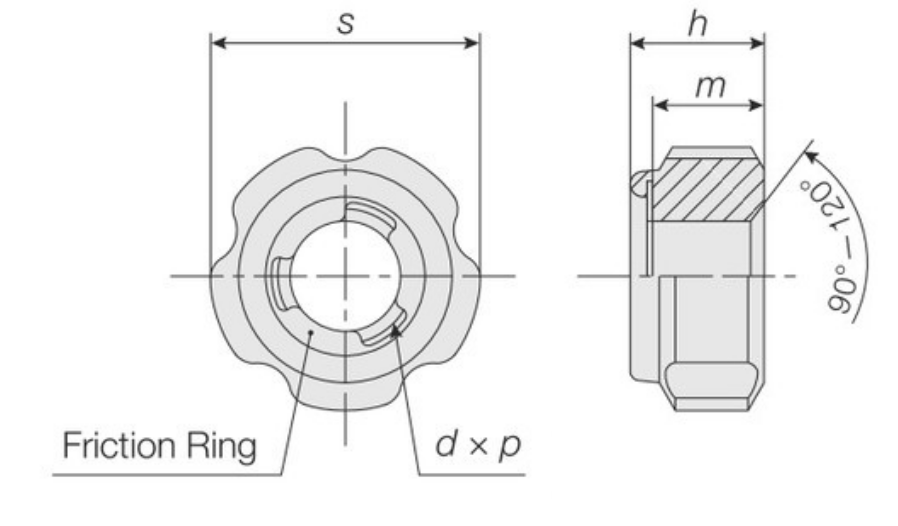

Dimensional Charts and Reference Tightening Torque Charts

SU-NUT Material of the Nut Body SUS304

Dimensional Chart and Reference Tightening Torque Chart

Thread Accuracy: JIS6H(Class 2) Unit:mm

| Material of the Nut Body | SUS304 | Reference Tightening Torque (N・m) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material of the Friction Ring | SUS301 | |||||||||

| Nominal Diameter (d) |

Pitch (p) |

Overall Height(h) | Across Flat(s) | Thread Height (m) Approx. |

Unit Weight (g) Approx. |

Bolt | ||||

| Base | Tolerance | Base | Tolerance | Stainless Steel Proof Stress 300N/㎟ |

Strength Grade 50 210N/㎟ |

Strength Grade 70 450N/㎟ |

||||

| M6 | 1.0 | 6 | ±0.3 | 12 | 0 -0.2 |

5 | 3 | 6.5 | 4.6 | 9.8 |

Installation Instructions

-

The SU-NUT has a special shape to prevent theft. As a result, a dedicated socket is used to fasten it. It cannot be removed with commercially available sockets or spanners. Lightly screw the nut on until the friction ring touches the tip of thread portion of the bolt.

-

Prepare the dedicated socket.

-

A ratchet wrench or impact wrench can also be used. For tightening torque management, the use of preset torque wrenches or digital ratchets is convenient and reliable.

-

Precautions for Use

This product is used for fastening parts that are especially important.

Please observe the following rules when using this product.

-

Use bolts that have a chamfered tip with JIS6g (Class 2) thread accuracy.

-

Please refer to the reference tightening torque chart when tightening nuts.

-

Use lubricant if there is a risk of galling or sticking when screwing on or unscrewing nuts.

-

To fully demonstrate the locking function of the FUJILOK U-NUT, make sure that at least two full bolt threads come out of the friction ring.

-

Consult us if you are working with bolts with threads that have been machined (with keyways, pin holes, etc.).

-

Use impact wrenches at a medium or lower rotating speed.

-

The nut cannot be screwed on from the friction ring side.

-

Stop using the FUJILOK U-NUT if abnormal deformation or other faults occur on the friction ring and clamp.

-

Consult us before using the FUJILOK U-NUT under severe conditions or with low axial force.