FSW U-NUT

An integrated the FUJILOK U-NUT and washer unit

Features

- An integrated the FUJILOK U-NUT and washer unit

- Reduces the number of components

- Makes construction easy and reduces costs

- Can also be used for anchor bolts

- Protects the surface treatment of the object the nut is being fastened onto

- Suitable for slotted holes and clearance holes

- Vibration impact tested in accordance with NAS3350

General names

Washer nut

Video of features

Applicable markets

- Two-wheeled vehicles

- Four-wheeled vehicles

- Special-equipped vehicles

- Farm equipment

- Conveyers

- Railways

- Marine vessels

- Plants

- Machine tools

- Industrial equipment

- Electronics

- Medical care and welfare

- Infrastructure

- Civil engineering

- Architecture

- Playground equipment

Basic Information

Specs

| Applications | ・Anti-loosening measures for anchor bolts ・Fixing support brackets for various cables ・Tunnel lighting installation work ・Pipe fitting installation work |

|---|---|

| Thread accuracy | JIS6H (JIS Class 2) |

| Sizes | SS M8~M16 SUS M6~M16 *Pitch: Coarse thread |

| Materials | SS400 or equivalent, SUS304 or equivalent |

| Surface treatments | Hot-dip Galvanizing Coating(SS400 or equivalent only) |

Dimensional Charts and Reference Tightening Torque Charts

FSW U-NUT Mateial of the Nut Body SS400 Hot-dip Galvanizing Coating

Dimensional Chart and Reference Tightening Torque Chart

Thread Accuracy: JIS6H(Class 2) Unit:mm

| Material of the Nut Body | SS400 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material of the Friction Ring | SUS301 | |||||||||||

| Material of the Washer | SPCC | |||||||||||

| Surface treatment | Hot-dip Galvanizing Coating | |||||||||||

| Nominal Diameter (d) |

Pitch (p) |

Width Across Flat (s) |

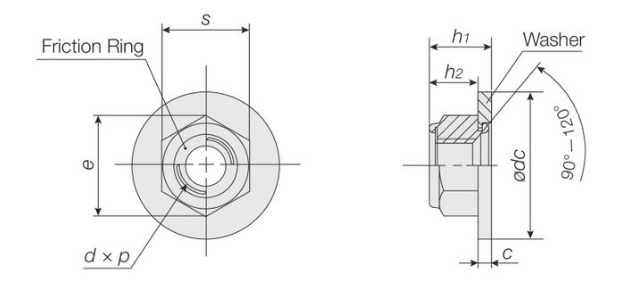

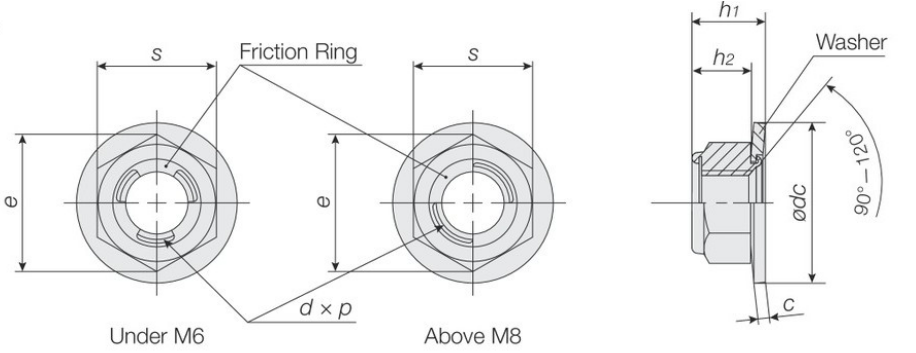

Flange Diameter (φdc) |

Overall Height (h1) |

U-NUT Height (h2) Approx. |

Across Corners (e) Approx. |

Washer Thickness (c) Approx. |

Unit Weight (g) Approx. |

Reference Tightening Torque(N・m) Bolt Strength Grade:4.8 Surface treatment: Hot-dip Galvanizing Coating |

|||

| Base | Tolerance | Base | Tolerance | Base | Tolerance | |||||||

| M8 | 1.25 | 13 | 0 -0.25 |

22 | 0 -0.52 |

9.3 | +1.0 -0.5 |

7.3 | 15.0 | 2.0 | 9.2 | 23.0 |

| M10 | 1.5 | 17 | 26 | 10.8 | 8.3 | 19.6 | 2.5 | 17.6 | 45.0 | |||

| M12 | 1.75 | 19 | 0 -0.35 |

32 | 0 -0.62 |

13.5 | 10.5 | 21.9 | 3.0 | 29.3 | 79.0 | |

| M16 | 2 | 24 | 38 | 17.5 | 14.5 | 27.7 | 3.0 | 50.6 | 195.0 | |||

FSW U-NUT Mateial of the Nut Body SUS304

Dimensional Chart and Reference Tightening Torque Chart

Thread Accuracy: JIS6H(Class 2) Unit:mm

| Material of the Nut Body/Material of the Washer | SUS304 | Reference Tightening Torque(N・m) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material ofthe Friction Ring | SUS301 | Bolt | ||||||||||||

| Nominal Diameter (d) |

Pitch (p) |

Width Across Flat (s) |

Flange Diameter (φdc) |

Overall Height (h1) |

U-NUT Height (h2) Approx. |

Across Corners (e) Approx. |

Washer Thickness (c) Approx. |

Unit Weight (g) Approx. |

Stainless Steel Proof Stress 300N/㎟ |

Strength Grade 50 210N/㎟ |

Strength Grade 70 450N/㎟ |

|||

| Base | Tolerance | Base | Tolerance | Base | Tolerance | |||||||||

| M6 | 1 | 10 | 0 -0.2 |

17 | 0 -0.4 |

6.5 | ±0.4 | 5.1 | 11.5 | 1.0 | 3.5 | 6.5 | 4.6 | 9.8 |

| M8 | 1.25 | 13 | 0 -0.25 |

20 | 9.2 | ±0.5 | 73.0 | 15.0 | 1.4 | 7.9 | 16.0 | 11.0 | 24.0 | |

| M10 | 1.5 | 17 | 24 | 10.6 | 83.0 | 19.6 | 1.8 | 14.6 | 31.0 | 22.0 | 47.0 | |||

| M12 | 1.75 | 19 | 0 -0.35 |

28 | 13.5 | 10.5 | 21.9 | 2.3 | 21.5 | 55.0 | 38.0 | 82.0 | ||

| M16 | 2 | 24 | 34 | 0 -0.5 |

18.0 | ±0.6 | 14.5 | 27.7 | 2.5 | 45.6 | 135.0 | 95.0 | 205.0 | |

Surface treatments

Precautions for Use

This product is used for fastening parts that are especially important.

Please observe the following rules when using this product.

-

Use bolts that have a chamfered tip with JIS6g (Class 2) thread accuracy.

-

Please refer to the reference tightening torque chart when tightening nuts.

-

Use lubricant if there is a risk of galling or sticking when screwing on or unscrewing nuts.

-

To fully demonstrate the locking function of the FUJILOK U-NUT, make sure that at least two full bolt threads come out of the friction ring.

-

Consult us if you are working with bolts with threads that have been machined (with keyways, pin holes, etc.).

-

Use impact wrenches at a medium or lower rotating speed.

-

The nut cannot be screwed on from the friction ring side.

-

Stop using the FUJILOK U-NUT if abnormal deformation or other faults occur on the friction ring and clamp.

-

Consult us before using the FUJILOK U-NUT under severe conditions or with low axial force.