Manufactured with Fuji Seimitsu’s cutting-edge equipment and technology, the FUJILOK U-NUT has a high locking effect and maintains high quality. Robust quality control is essential for attaining stable quality. At Fuji Seimitsu, each and every employee is aware that nuts are key parts that affect product performance, and our Quality Assurance Department plays a central role in quality control. With our quality control, only products that have passed various safety standards and inspections are shipped, and we take great care not to produce defective products. If any defect or problem occurs while a customer is using one of our products, we will investigate the cause to the very end by reproducing the usage conditions based on various measuring devices and interviews.

In this article, we will introduce items related to installation methods as examples of problems and solutions that occur with nuts.

How to install the FUJILOK U-NUT

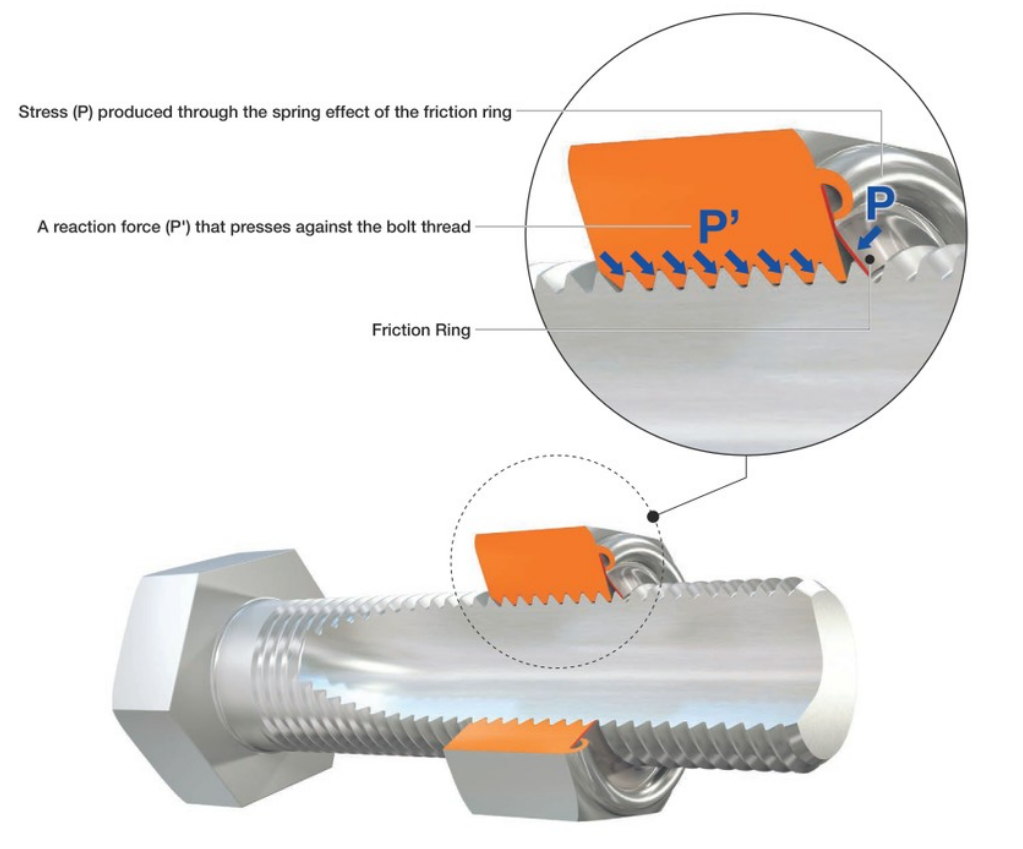

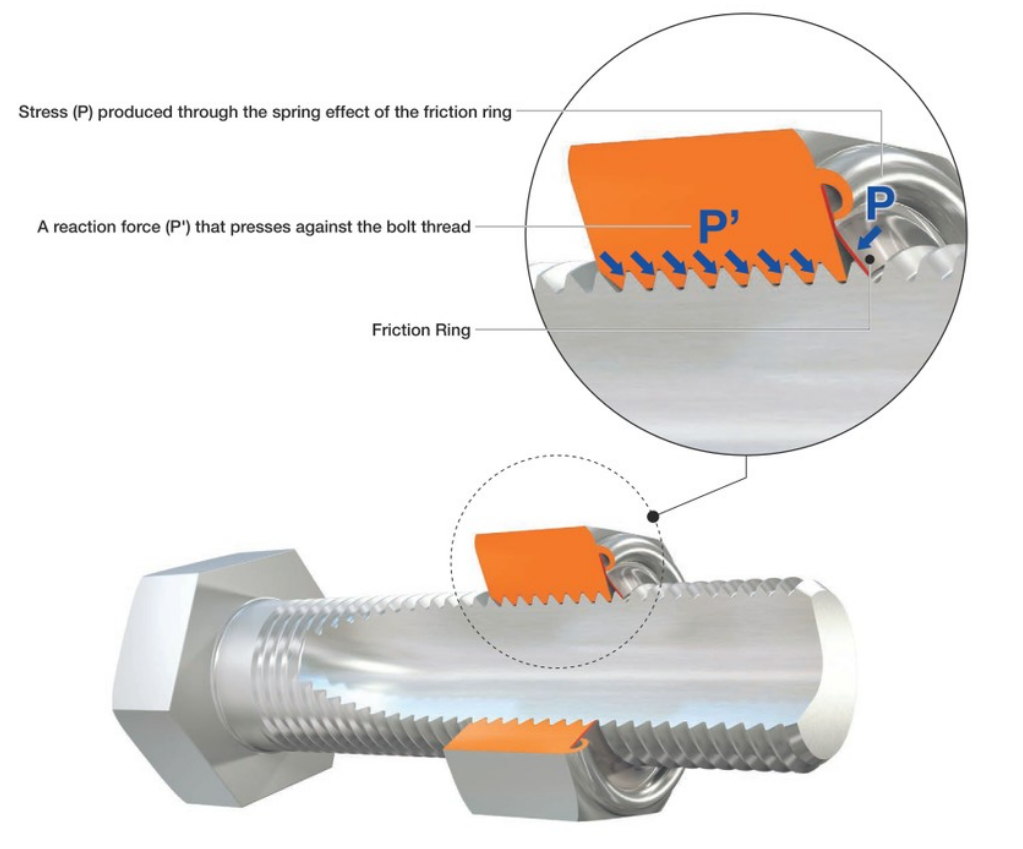

the FUJILOK U-NUT demonstrates a locking effect through its friction ring (specialized spring), which is secured to and integrated with the top face of the nut body by crimping. The force of the spring attempting to return to its original state (stress) that occurs when the friction ring presses down on the bolt screw threads, and the force of the bolt and nut screw pulling each other (reaction force) generate prevailing torque (friction torque), preventing the FUJILOK U-NUT from loosening.

A tightening tool such as a wrench is required to install the FUJILOK U-NUT. Until the friction ring touches the tip of the thread portion of the bolt, the FUJILOK U-NUT can be turned by hand like a normal nut (please note that it cannot be screwed in from the friction-ring side). After the friction ring comes into contact with the bolt threads, tighten the nut with a tightening tool. When tightening, check the reference tightening torque chart provided in one of our catalogs, etc., and tighten the nut with appropriate torque. After tightening, check that at least two full bolt threads come out of the friction ring, and make sure that the locking effect is fully exerted. When removing the nut, use a tightening tool to turn the nut until the friction ring is separated from the tip of the threaded portion of the shaft.

Properly using the FUJILOK U-NUT allows it to stably exert a solid locking effect over a long period of time.

Over-tightening of the nut can cause deformation of the nut and damage to the seat surface of the nut or the object the nut is being fastened onto. Since the bolt will also be extended, proper axial force is not applied, resulting in the nut becoming loose and falling off. Over-tightening of the nut can be determined by checking the state of the nut (deformation of the nut) with various measuring devices.

Examples of nuts with scratched or deformed seat surfaces

If the nut is not tightened enough, the axial force will be insufficient, and the nut will rotate in the loosening direction due to vibration, etc., causing the nut to fall off. the FUJILOK U-NUT demonstrates a locking effect that cannot be easily turned by hand, even at the middle position of the bolt, due to the prevailing torque generated by the friction ring and bolt threads. However, if the axial force is continuously applied in a state of low axial force where the tightening is not sufficient, the prevailing torque will decrease, and the nut may rotate in the loosening direction and fall off. You can guess when a nut has not been tightened enough because there are no seating marks on the underside of the nut.

The appropriate tightening torque for the nut depends on characteristics such as the size, material, and surface treatment of the nut, so make sure to confirm what the appropriate value is. In addition, it is important not to rely on intuition for tightening force but to follow the proper installation procedure for the nut, prepare a work procedure manual, and manage the torque properly in order to prevent loosening, fracturing of the bolt, and dropout.

Untapered bolts

When the friction ring comes into contact with the tip of the thread portion, it begins to bend upward along the slope of the thread, generating a prevailing torque. When this happens, if the bolt end is flat, the friction ring will not bend and may get caught along the downward slope of the thread. If the nut continues to be turned in this state, the friction ring will be twisted off, and a locking effect will not be exerted. The nut will then need to be replaced.

A nut with a broken friction ring and a normal nut

The bolt that the FUJILOK U-NUT will be installed on must have been chamfered at the tip of the threaded portion with a thread accuracy of JIS6g (formerly Class 2). If the chamfer width is too small, it may cause the same problem as if it were flat, so make sure that the taper (chamfer) is at or above a certain width.

As a unique example, there have been cases where the friction ring and nut itself were damaged and loosened when the nut was tightened by being struck in the direction of rotation for the nut. Therefore, please make sure to first confirm the installation method and then install the nut using the appropriate method.

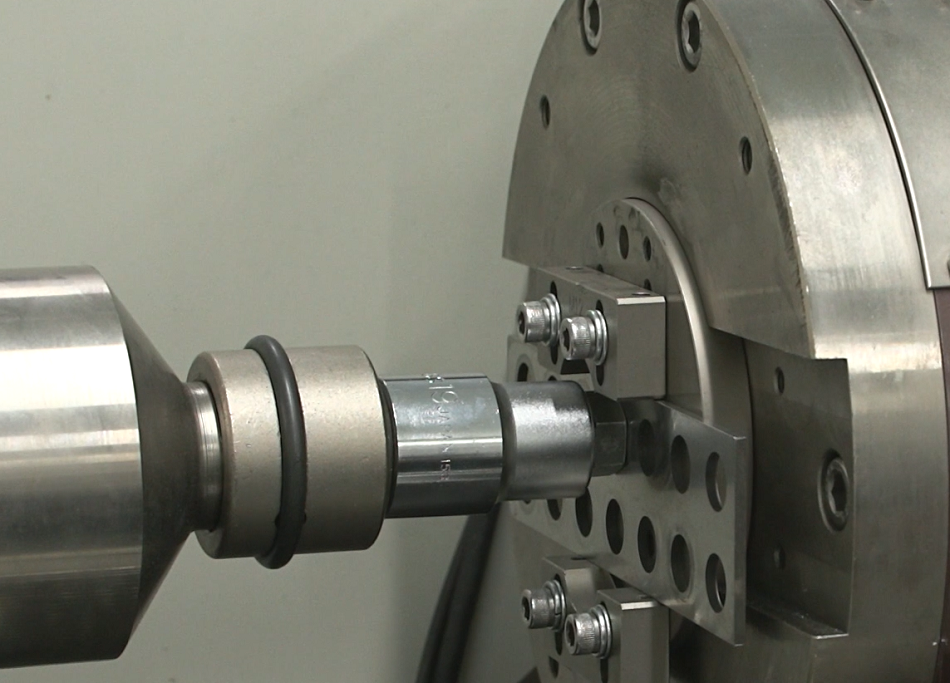

Threaded Fastener Tightening Characteristics Testing Machine

Many of the problems associated with use are invisible, so even if the problem is solved once, we will check after some time has passed to see if the issue has recurred. In addition, if you have a problem with bolts or nuts, even if it’s unrelated to the FUJILOK U-NUT, contact us, and we can handle your issues. We also provide support for overseas customers. Fuji Seimitsu offers a wide range of support to resolve the challenges that our customers experience with nuts and bolts. Please feel free to contact us.

A tightening tool such as a wrench is required to install the FUJILOK U-NUT. Until the friction ring touches the tip of the thread portion of the bolt, the FUJILOK U-NUT can be turned by hand like a normal nut (please note that it cannot be screwed in from the friction-ring side). After the friction ring comes into contact with the bolt threads, tighten the nut with a tightening tool. When tightening, check the reference tightening torque chart provided in one of our catalogs, etc., and tighten the nut with appropriate torque. After tightening, check that at least two full bolt threads come out of the friction ring, and make sure that the locking effect is fully exerted. When removing the nut, use a tightening tool to turn the nut until the friction ring is separated from the tip of the threaded portion of the shaft.

Properly using the FUJILOK U-NUT allows it to stably exert a solid locking effect over a long period of time.

Problems caused by over-tightening or under-tightening

When the FUJILOK U-NUT is not tightened with the proper tightening torque, it is unable to exert a sufficient locking effect, and this may result in the FUJILOK U-NUT becoming loose and falling off unexpectedly. It doesn’t matter if the nut is over-tightened or not tightened enough. Both situations cause the axial force to decrease and make loosening more likely to occur. It’s important to securely tighten the nut with the appropriate torque.Over-tightening of the nut can cause deformation of the nut and damage to the seat surface of the nut or the object the nut is being fastened onto. Since the bolt will also be extended, proper axial force is not applied, resulting in the nut becoming loose and falling off. Over-tightening of the nut can be determined by checking the state of the nut (deformation of the nut) with various measuring devices.

Examples of nuts with scratched or deformed seat surfaces

If the nut is not tightened enough, the axial force will be insufficient, and the nut will rotate in the loosening direction due to vibration, etc., causing the nut to fall off. the FUJILOK U-NUT demonstrates a locking effect that cannot be easily turned by hand, even at the middle position of the bolt, due to the prevailing torque generated by the friction ring and bolt threads. However, if the axial force is continuously applied in a state of low axial force where the tightening is not sufficient, the prevailing torque will decrease, and the nut may rotate in the loosening direction and fall off. You can guess when a nut has not been tightened enough because there are no seating marks on the underside of the nut.

The appropriate tightening torque for the nut depends on characteristics such as the size, material, and surface treatment of the nut, so make sure to confirm what the appropriate value is. In addition, it is important not to rely on intuition for tightening force but to follow the proper installation procedure for the nut, prepare a work procedure manual, and manage the torque properly in order to prevent loosening, fracturing of the bolt, and dropout.

Problems caused by bolt shape

Problems caused by the shape of the bolt end are another type of issue that can happen with the FUJILOK U-NUT depending on how it’s installed. Many bolt ends are tapered (chamfered) to facilitate entry into the nut hole. However, in rare cases, there is no taper (chamfer), and attaching a U-NUT to a bolt like this causes problems with the friction ring.

Untapered bolts

When the friction ring comes into contact with the tip of the thread portion, it begins to bend upward along the slope of the thread, generating a prevailing torque. When this happens, if the bolt end is flat, the friction ring will not bend and may get caught along the downward slope of the thread. If the nut continues to be turned in this state, the friction ring will be twisted off, and a locking effect will not be exerted. The nut will then need to be replaced.

A nut with a broken friction ring and a normal nut

The bolt that the FUJILOK U-NUT will be installed on must have been chamfered at the tip of the threaded portion with a thread accuracy of JIS6g (formerly Class 2). If the chamfer width is too small, it may cause the same problem as if it were flat, so make sure that the taper (chamfer) is at or above a certain width.

As a unique example, there have been cases where the friction ring and nut itself were damaged and loosened when the nut was tightened by being struck in the direction of rotation for the nut. Therefore, please make sure to first confirm the installation method and then install the nut using the appropriate method.

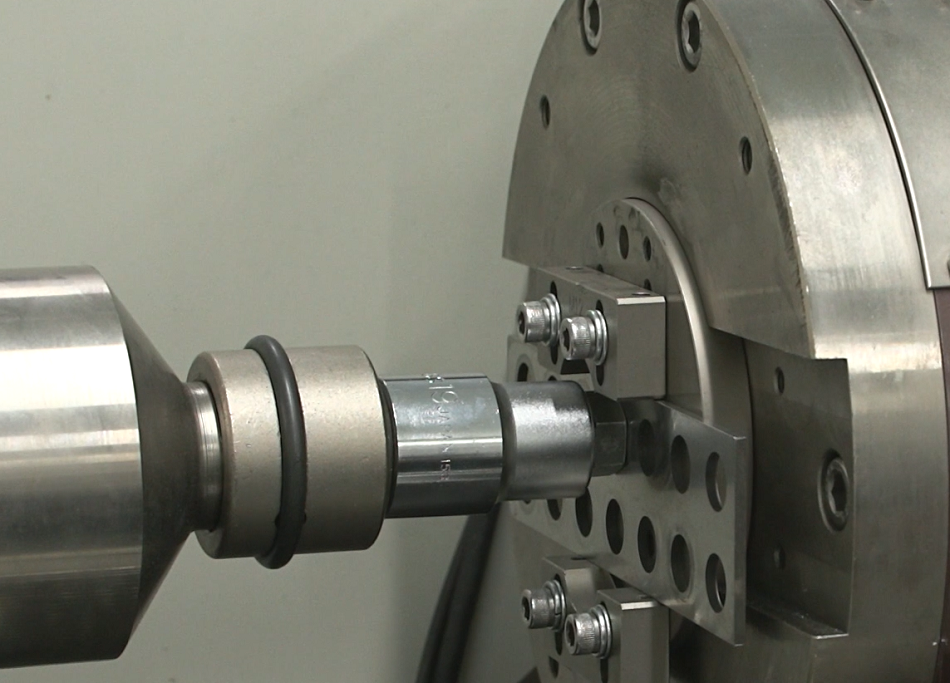

Verifying the causes of problems from all angles

Fuji Seimitsu investigates the causes of defects and problems that occur in U-NUTs and provides support until the customer is satisfied. Not only do we inspect the actual product with various measuring devices that we own, but we also verify the situation by interviewing customers about usage conditions. For example, if the nut is over-tightened or under-tightened, we will use a torque measurement wrench to determine the amount of torque used to tighten the nut or to reproduce the actual tightening torque and verify the conditions. This allows us to have an accurate understanding of what is happening on-site.

Threaded Fastener Tightening Characteristics Testing Machine

Many of the problems associated with use are invisible, so even if the problem is solved once, we will check after some time has passed to see if the issue has recurred. In addition, if you have a problem with bolts or nuts, even if it’s unrelated to the FUJILOK U-NUT, contact us, and we can handle your issues. We also provide support for overseas customers. Fuji Seimitsu offers a wide range of support to resolve the challenges that our customers experience with nuts and bolts. Please feel free to contact us.