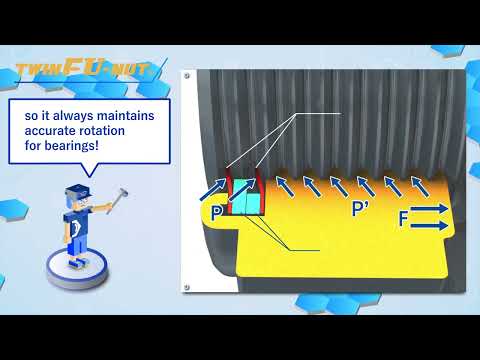

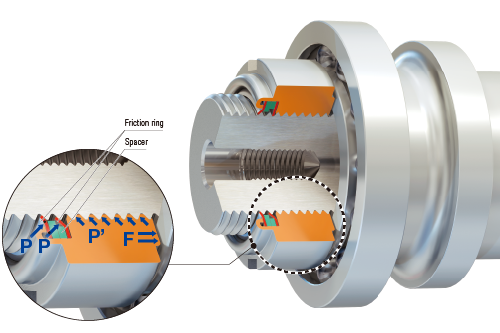

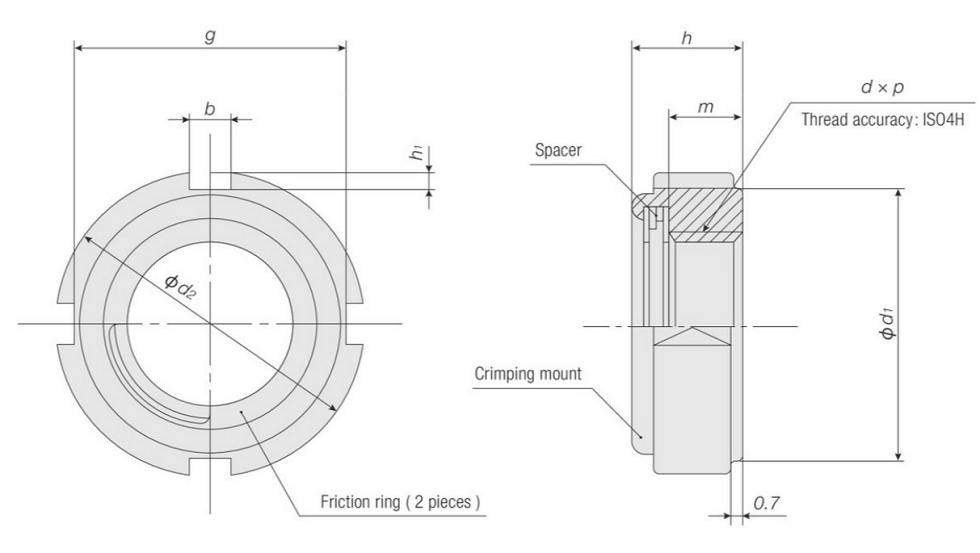

"TWIN FU-NUT" has two friction rings and two spacers that have been installed and fixed to the top of the nut. The two friction rings are arranged so that the forces (P) and (P') generated by the spring effect act equally in the symmetric direction of the screw axial core, and the bearing can be fastened with an even surface load (F).

TWIN FU-NUT

A prevailing-torque-type precision locknut

Features

- Performance enhancement:

Enhances the locking performance of the FINE U-NUT - Simple fastening:

Just tighten the nut to complete fastening - Reusability:

Can be reused - Thread accuracy:

ISO4H thread accuracy - Surface run-out accuracy:

The accuracy of seat surface run-out in relation to the screw is 1,000 minutes (mm)

General names

Precision bearing nut, Adapter nut, Grooved round nut, Precision locknut

Video of features

Applicable markets

- Two-wheeled vehicles

- Four-wheeled vehicles

- Special-equipped vehicles

- Farm equipment

- Conveyers

- Railways

- Marine vessels

- Plants

- Machine tools

- Industrial equipment

- Electronics

- Medical care and welfare

- Infrastructure

- Civil engineering

- Architecture

- Playground equipment

Structure & Function

Structure description video

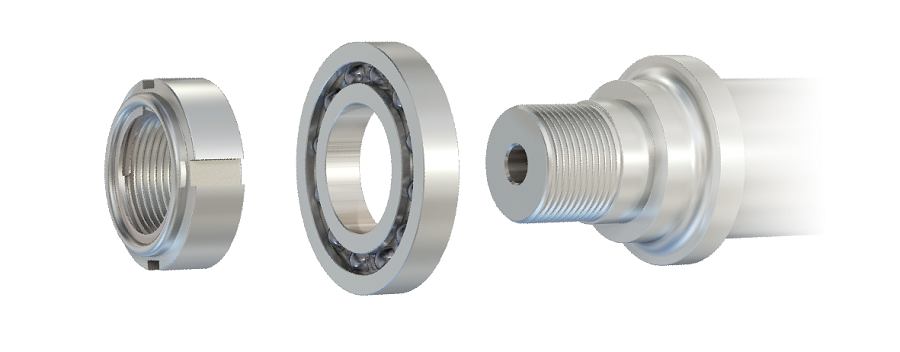

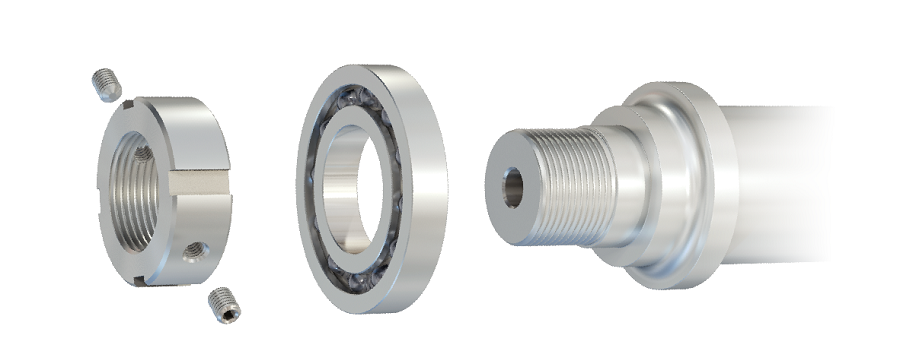

The TWIN FU-NUT vs. Conventional Product

TWIN FU-NUT

- Consists of 3 basic parts.

- Just insert to fasten.

Conventional product

- Consists of 5 basic parts.

- Fixed with setting screws.

Basic Information

Specs

| Steel friction ring | 270°ring |

|---|---|

| Thread accuracy | ISO4H Screw and seat surface are machined simultaneously. |

| Sizes | M15 to M50 (up to M110 can be supported) *Pitch: Fine thread *Other special sizes |

| Shapes | Grooved round nut |

| Materials | Nut body . . . S45C (thermal refined) Friction ring,Spacers . . . SUS301 |

| Surface treatments | Zinc Phosphate Coating |

Dimensional Charts

TWIN FU-NUT Dimensional Chart

Thread accuracy:ISO4H Unit:mm

| Part No. | d×p | Flange Diameter (φd1) |

Outside Diameter (φd2) |

Overall Height (h) |

Thread Height (m) Approx. |

Width of locknut slot (b) |

Depth of locknut slot (h1) |

Locknut slot opposite side (g) |

Thread accuracy length ℓmin |

Unit Weight (g) Approx. |

Allowable Axial Dead load (kN) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TFU02SC | M15 × 1 | 21.0 | 0 -0.3 |

25 | 0 -0.5 |

9.9 | ±0.5 | 7 | 4 | ±0.2 | 1.8 | 21.4 | 0 -0.5 |

10.5 | 19.0 | 34.1 |

| TFU03SC | M17 × 1 | 23.5 | 28 | 10.1 | 7 | 4 | 2.0 | 24.0 | 10.5 | 24.0 | 38.6 | |||||

| TFU04SC | M20 × 1 | 27.0 | 32 | 12.3 | 9 | 4 | 2.0 | 28.0 | 12.5 | 38.0 | 59.4 | |||||

| TFU05SC | M25 × 1.5 | 33.0 | 38 | 14.2 | 10 | 5 | 2.0 | 34.0 | 15.3 | 59.0 | 80.8 | |||||

| TFU06SC | M30 × 1.5 | 40.0 | 45 | 14.3 | 10 | 5 | 2.0 | 41.0 | 15.3 | 82.0 | 97.0 | |||||

| TFU07SC | M35 × 1.5 | 47.0 | 52 | 16.5 | 12 | 5 | 2.0 | 48.0 | 17.3 | 125.0 | 137.8 | |||||

| TFU08SC | M40 × 1.5 | 52.0 | 58 | 17.6 | 13 | 6 | 2.5 | 53.0 | 18.3 | 150.0 | 171.4 | |||||

| TFU09SC | M45 × 1.5 | 59.0 | 65 | 19.7 | 15 | 6 | 2.5 | 60.0 | 20.3 | 210.0 | 224.5 | |||||

| TFU10SC | M50 × 1.5 | 64.0 | 70 | 20.8 | 16 | 6 | 2.5 | 65.0 | 21.3 | 255.0 | 266.8 | |||||

Surface treatments

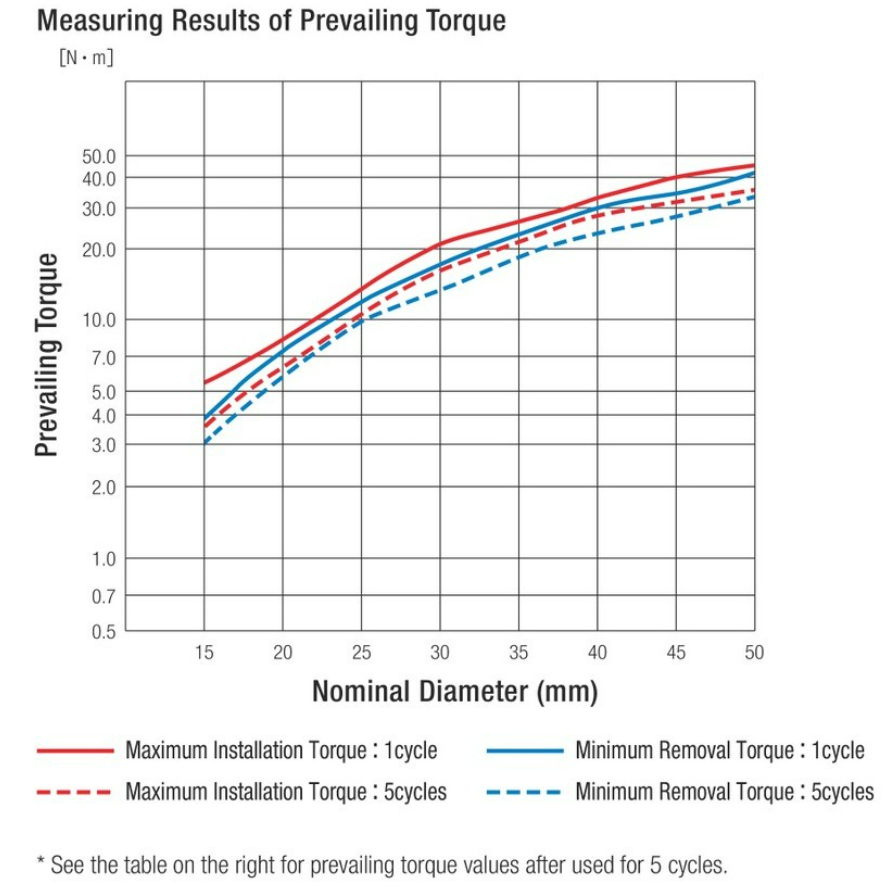

Prevailing Torque

Performance of the privailing torque and reusability

Prevailing torque is produced by the spring effect when the friction ring touches the bolt threads.

| TFU04SC M20×1 | |||

|---|---|---|---|

| Maximum Installation torque | Minimum removal torque | ||

| 1cycle | 5cycle | 1cycle | 5cycle |

| 8.5 | 6.5 | 7.5 | 6.0 |

Even re-used 5 times, the prevailing torque shows only a slight decrease.

Test Condition

| Bolt material | SCM435H |

|---|---|

| Thread accuracy | ISO 4h |

| Surface treatment | Zinc Phosphate Coating(nut), plain(shaft) |

| Lubricant | penetrating lubricant |

Installation Instructions

-

Thread the bearing through the shaft thread. Check that the tip of the shaft thread has been chamfered (C = 1 pitch or equivalent) before applying lubricant.

-

Manually screw the nut on until the friction ring touches the tip of thread portion of the shaft.

-

Check that the friction ring is in contact with the tip of the shaft thread.

-

Use a tightening tool made especially for the "FINE U-NUT."

*A hook wrench can also used to remove the nut.

*An impact wrench cannot be used. -

Push down on the axis portion of the ratchet handle and gently turn the ratchet to tighten.

-

Check that the inner ring of the bearing is in complete contact with the seat surface of "TWIN FU-NUT," and that at least two full shaft threads come out of the friction ring.

-

-

Precautions for Use

This product is used for fastening parts that are especially important.

Please observe the following rules when using this product.

-

Clean the threaded portion of the shaft when screwing on or unscrewing the nut.

-

A thread accuracy of 4h (ISO standard) is recommended for the shaft thread.

Chamfer (C = 1 pitch or equivalent) the tip of the threaded portion of the shaft. -

Be sure that there are no burrs or dents on the chamfer or threaded portion of the shaft.

-

Use lubricant when screwing on or unscrewing the nut. (If there is a risk that chipping may occur, use a lubricant with especially high lubricating performance. )

-

To fully demonstrate the locking function of the FINE U-NUT, make sure that at least two full bolt threads come out of the friction ring.

*Refer to the dimensional chart for extra shaft thread dimensions. -

To prevent the nut from hitting one side, it is necessary to tighten the nut by about 1.2 times the prevailing torque or more.

*Please contact us about prevailing torque. -

The nut cannot be used if the threaded portion of the shaft is machined (keyway, etc.).

*If you are using a shaft with a keyway, etc., please consult with us. -

An impact wrench cannot be used.

-

The nut cannot be screwed on from the friction ring side.

-

Stop using the FUJILOK U-NUT if abnormal deformation or other faults occur on the friction ring and clamp.

-

Consult us before using the FUJILOK U-NUT under severe conditions or with low axial force.