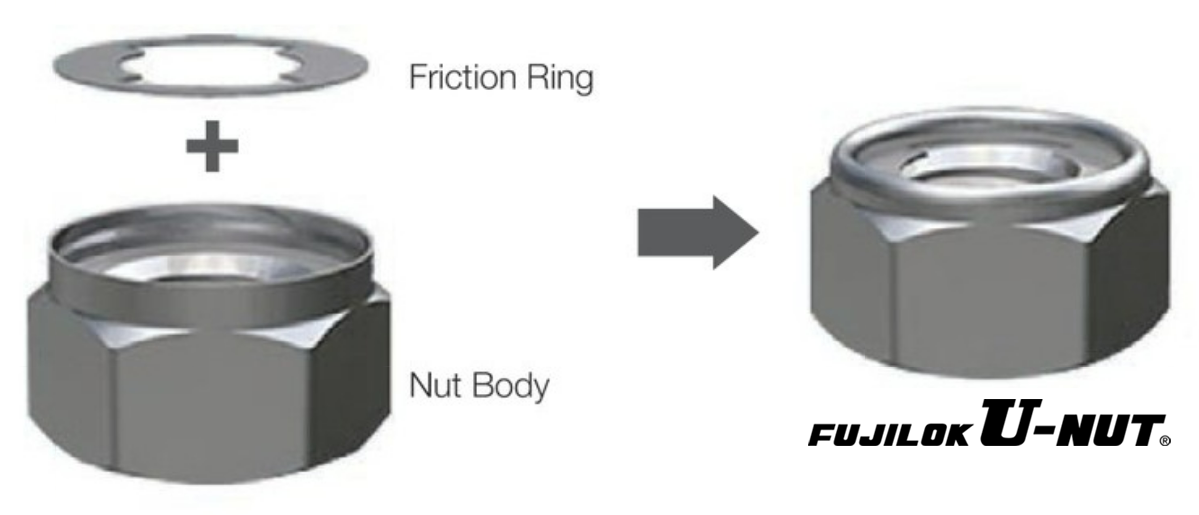

The FUJILOK U-NUT consists of a nut and friction ring (specialized ring).The friction ring is secured to and integrated with the top face of the nut by crimping.

FUJILOK U-NUT

The FUJILOK U-NUT has built up a record of trust and excellent performance since its creation over 50 years ago

Features

- Fastening function:

Demonstrates stable locking function - Dropout prevention:

Prevents premature detachment even if the tightening force is lowered - Reusability:

Can be reused - Simple fastening:

Easy tightening with no need for skilled techniques or specialized tools - Simplex parts:

It demonstrates a locking effect by itself, making parts management easy and preventing installation errors - Heat and cold resistance:

An all-metal product with excellent resistant to heat and cold

General names

Locknut, Prevailing-torque-type nut

Applicable markets

- Two-wheeled vehicles

- Four-wheeled vehicles

- Special-equipped vehicles

- Farm equipment

- Conveyers

- Railways

- Marine vessels

- Plants

- Machine tools

- Industrial equipment

- Electronics

- Medical care and welfare

- Infrastructure

- Civil engineering

- Architecture

- Playground equipment

Lineup *Dimensional charts and tightening torque charts can be found here.

Structure & Function

The industry's first [Metal ring locking function]

Structure description video

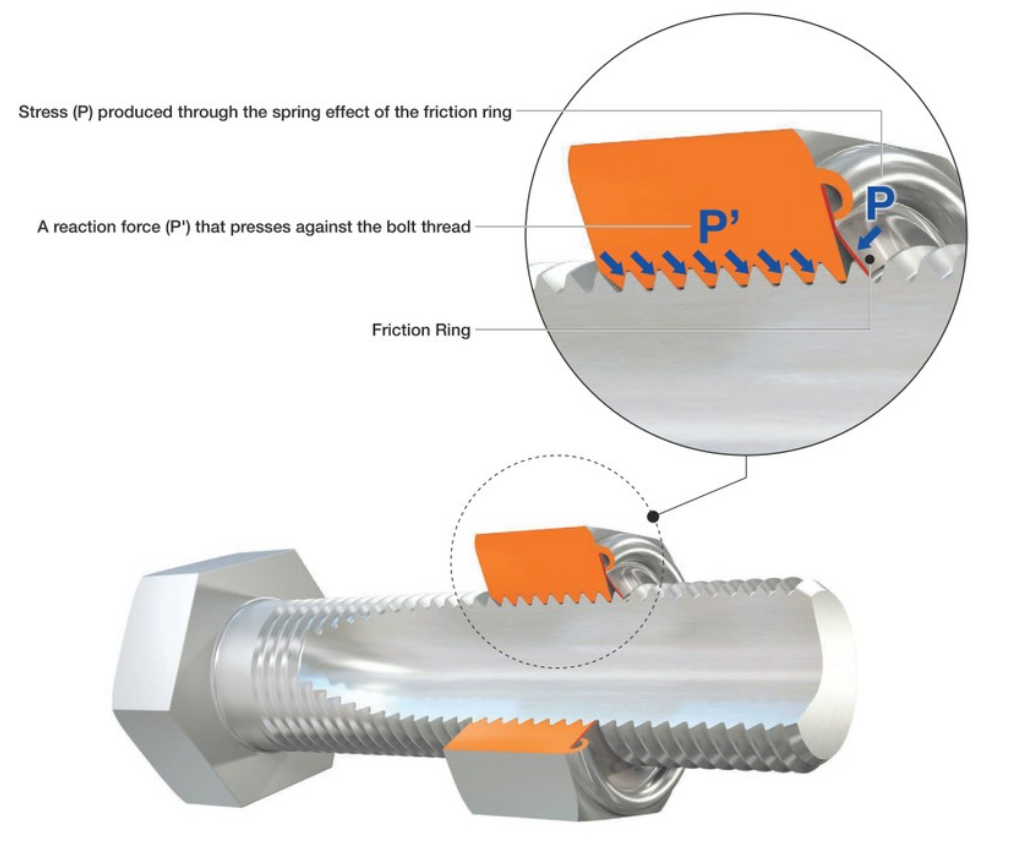

The friction ring touches the bolt screw threads, and stress (P) is produced through a spring effetct when the nut is tightened as shown on the left. Along with a reaction force (P'), a frictional torque (prevailing torque=P) that presses against the bolt screw threads is produced.

▼

Prevents free rotation

Basic Information

Specs

| Steel friction ring | 60° 3-wing ring (up to M6) 90° 2-wing ring (M8 and above) |

|---|---|

| Thread accuracy | JIS6H(JIS Class2),formerly JIS Class2, JIS2B |

| Sizes | M3 - M115 *Pitch: Coarse thread and fine thread W3/16-24 - W2"-4.5 NC#10-24 - NC1"1/2-6 NF#10-32 - NF1"1/2-12 *Other special sizes |

| Shapes | FUJILOK U-NUT Single Chamfer(Type 1), Double Chamfer (Type 2), Thin Type (Type 3), Small Type U-NUT, Flange Type U-NUT, Cap Type U-NUT, Weld Type U-NUT. |

| Materials | SS400 or equivalent, S45C thermal refined or equivalent, SUS304 or equivalent, SCM435 (thermal refined), titanium, SUS316L, brass (BSBM) *Other special materials |

Surface treatments

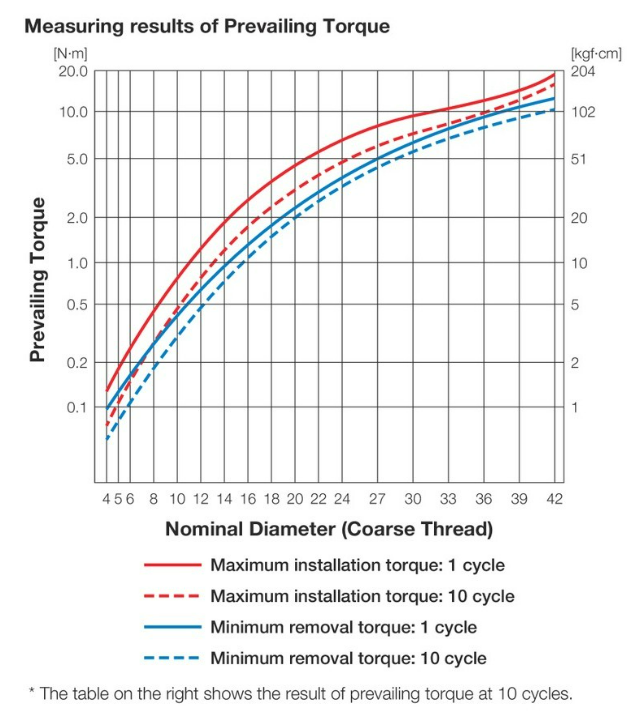

Prevailing Torque

Performance of the prevailing torque and reusability

Prevailing torque is produced by the spring effect when the friction ring touches the bolt threads.

| M12 × 1.75 SS400 equivalent non-plating | |||

|---|---|---|---|

| Maximum Installation torque | Minimum removal torque | ||

| 1cycle | 10cycle | 1cycle | 10cycle |

| 1.20 | 0.75 | 0.70 | 0.50 |

Even re-used 10 times, the prevailing torque shows only a slight decrease.

Test Conditions

| Bolt material | Alloy steel (SCM435) |

|---|---|

| Thread accuracy | ISO6g (JIS6g) |

| Surface treatment | plain (nut and bolt) |

| Lubricant | penetrating lubricant |

Tests

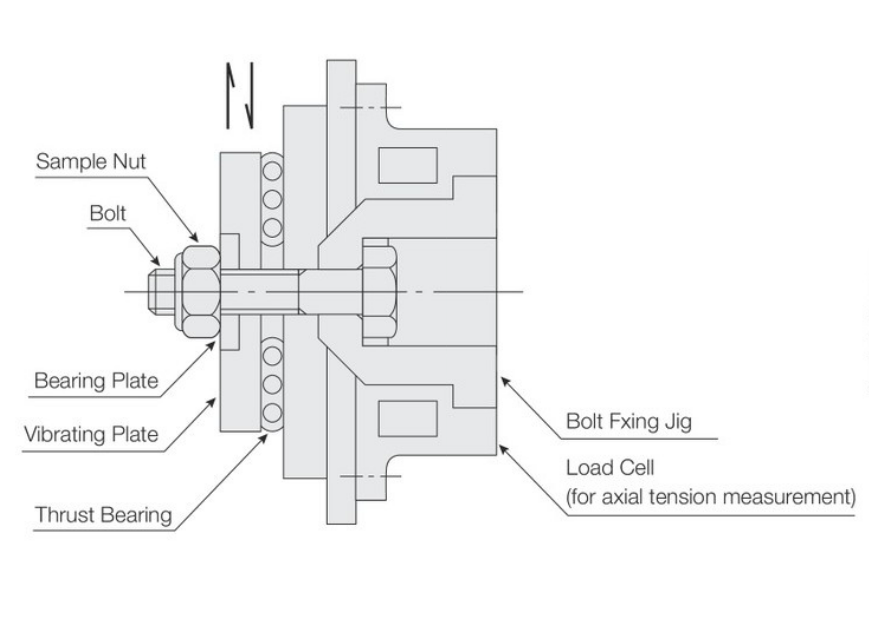

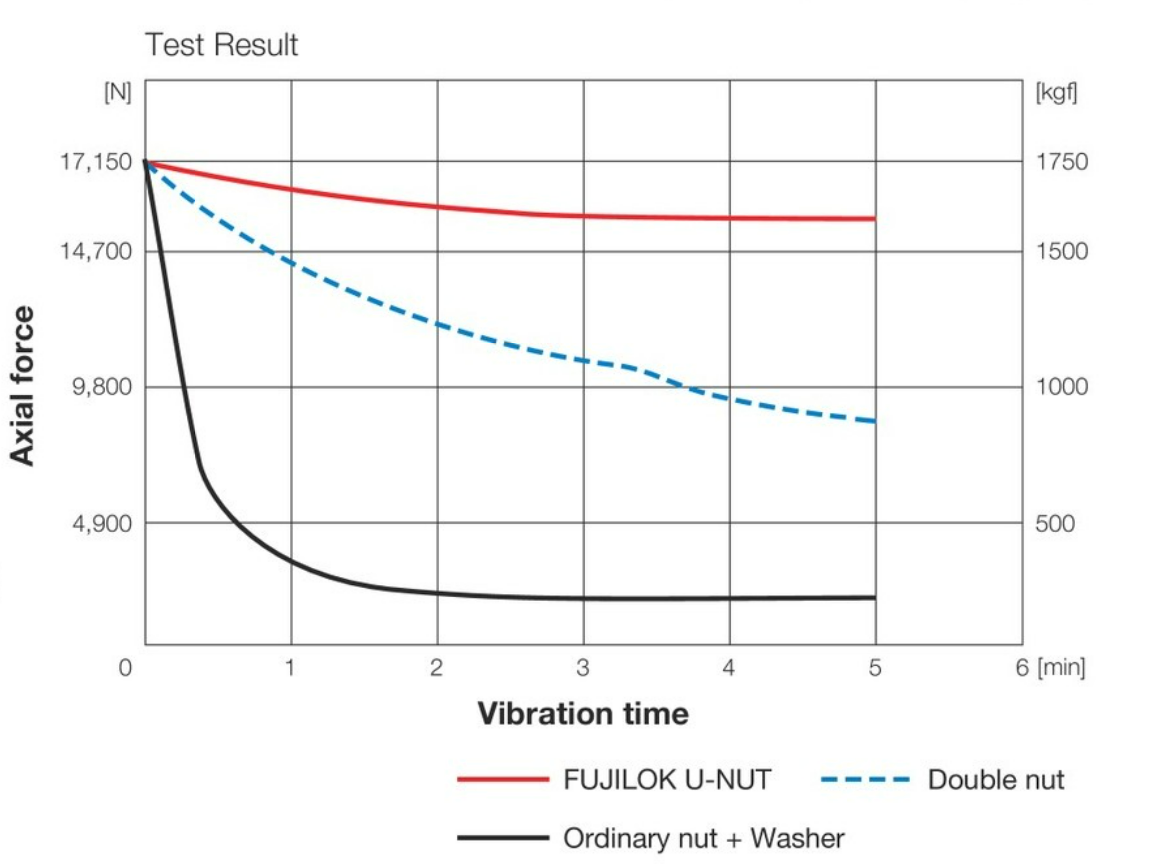

Vertical Axis Vibration Test

Junker Type Thread Looseness Test (according to DIN 65151)

This test repeatedly applies amplitude and impact in a direction vertical to the axis of the bolts and nuts that are assembled in a vibration plate in order to examine the reduced axial tension of the fastener and judge the locking performance.

Test Condition

| Sample size | M12×1.75 |

|---|---|

| Material of the sample nut, bolt | SS400 or equivalent |

| Axial tension for fastening | 17,150N{1,750kgf} |

Specification of the Junker Type Thread Loosening Testing Machine

| Frequency of the vibration plate | 200 c.p.m. |

|---|---|

| Displacement of vibration | ±0.5mm |

| Vibration time | 5min. |

Test Result

Vertical Axis Vibration Test video

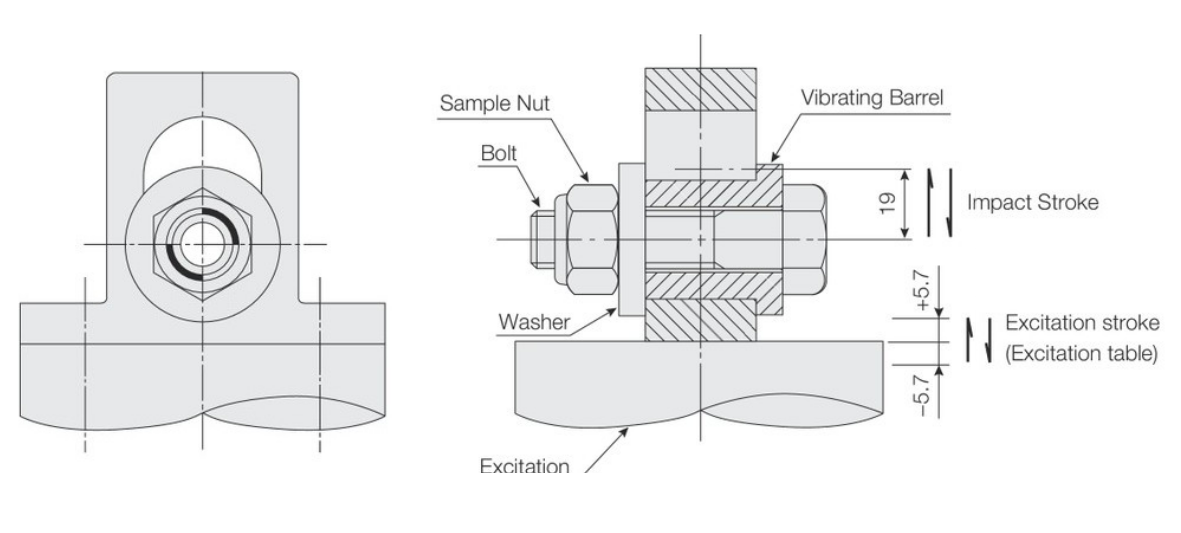

Vertical Axis Vibration Impact Test

NAS Conforming High Speed Thread Looseness Test (according to National Aerospace Standard NAS3350)

This test repeatedly applies shocks in a direction vertical to the axis of the bolts and nuts that are assembled a vibration barrel in order to examine whether or not loosening occurs and judge the locking performance.

Test Condition

| Sample size | M12×1.75 |

|---|---|

| Material of the sample nut, bolt | SS400 or equivalent |

| Axial tension for fastening | 17,150N{1,750kgf} |

Specification of NAS Conforming High Speed Thread Loosening Testing Machine

| Frequency | 1,780 c.p.m. |

|---|---|

| Excitation stroke | 11mm |

| Impact stroke | 19mm |

| Vibration acceleration of the excitation table |

19.5G |

Test Result

| Sample size | Frequency | Vibration time |

|---|---|---|

| FUJILOK U-NUT |

30,000cycles | 16' 51" |

| No problem | ||

| Double nut | 4,450cycles | 2' 30" |

| Came off | ||

| Ordinary nut + Washer |

1,335cycles | 45 sec. |

| Came off | ||

Vertical Axis Vibration Impact Test video

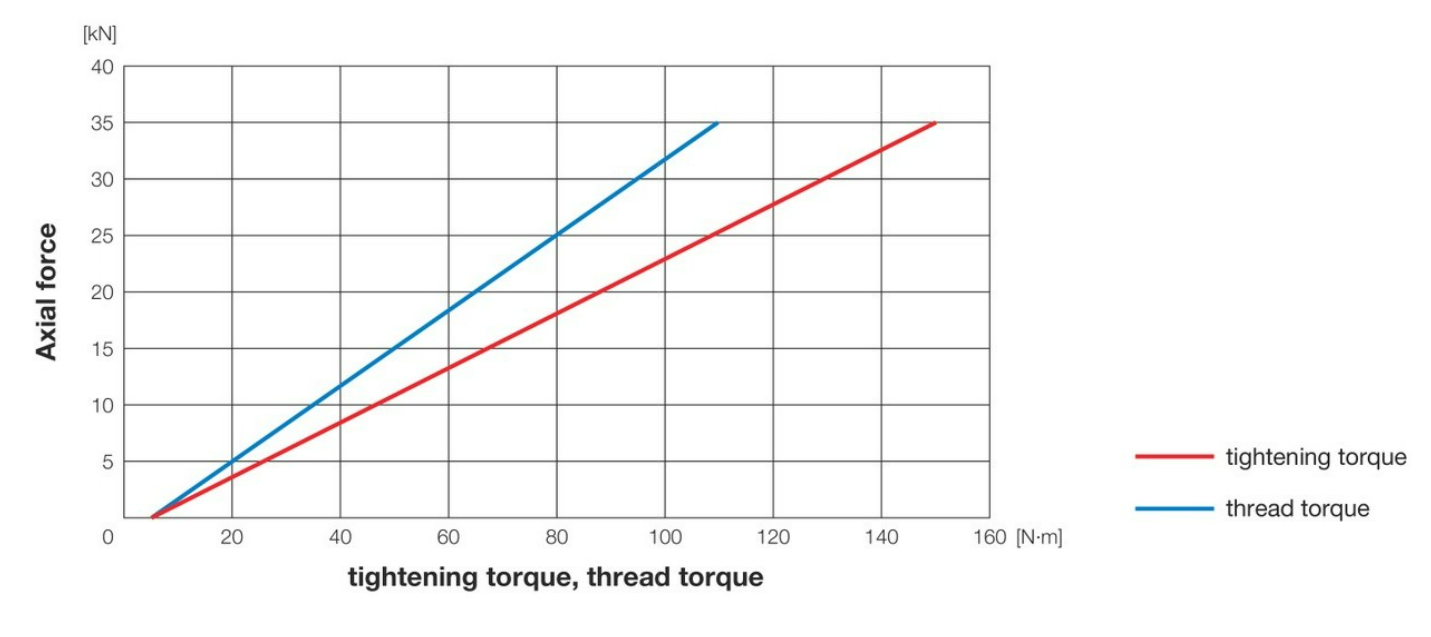

Threaded Fastener Tightening Characteristic Test

This test measures the axial force, tightening torque, and thread torque.

Test Result

Threaded Fastener Tightening Characteristic Test video

Installation Instructions

Installation with a wrench

-

Thread the bolt through the fastening member. Check that the bolt has been chamfered at the tip of the threaded area with a thread accuracy of JIS6g (Class 2). If there is risk of galling or sticking, use lubricant.

-

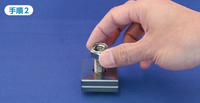

Manually screw the nut on until the friction ring touches the tip of thread portion of the bolt.

*The nut cannot be screwed on from the friction ring side. -

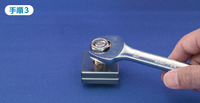

Tighten the nut with a tool such as a wrench/impact wrench. Please refer to the reference tightening torque chart for the tightening torque.

Please contact us if you will be using the FUJILOK U-NUT under severe conditions or with low axial force. -

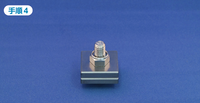

Check that at least two full bolt threads protrude beyond the friction ring.

When removing the nut, use a wrench or other such tool to unscrew the nut until the friction ring is separated from the tip of the threaded portion of the bolt.

Installation with an impact wrench

-

Thread the bolt through the fastening member. Check that the bolt has been chamfered at the tip of the threaded area with a thread accuracy of JIS6g (Class 2). If there is risk of galling or sticking, use lubricant.

-

Manually tighten the nut until the friction ring touches the tip of the thread portion of the bolt.

-

Tighten the nut on at low speed from directly above. Working while the bolt is slanted or installing the nut at high rotating speeds may cause galling.

-

Do not insert nuts into the socket of the impact wrench.

Precautions for Use

This product is used for fastening parts that are especially important.

Please observe the following rules when using this product.

-

Use bolts that have a chamfered tip with JIS6g (Class 2) thread accuracy.

-

Please refer to the reference tightening torque chart when tightening nuts.

-

Use lubricant if there is a risk of galling or sticking when screwing on or unscrewing nuts.

-

To fully demonstrate the locking function of the FUJILOK U-NUT, make sure that at least two full bolt threads come out of the friction ring.

-

When welding a nut, pay attention to sputtering and the effect of heat on the friction ring and bolt threads.

-

Consult us if you are working with bolts with threads that have been machined (with keyways, pin holes, etc.).

-

Use impact wrenches at a medium or lower rotating speed.

-

The nut cannot be screwed on from the friction ring side.

-

Stop using the FUJILOK U-NUT if abnormal deformation or other faults occur on the friction ring and clamp.

-

Consult us before using the FUJILOK U-NUT under severe conditions or with low axial force.